IPS is a family-owned and operated toll HIP company. We belong to a family of companies that stretches from the Pacific Northwest down to the Deep South and back up again to the Midwest.

On Time, As Promised — Always.

From Our Family Of Companies To Yours

Aerospace. Biomedical. Automotive. Defense. Power. Discovery and innovation with every partnership. Efficiencies hardwired into the process. Evolving applications. We’ll work hard for you from start to finish to ensure you have everything you need when you need it. The future is bright, and IPS stands ready to deliver it for you.

Unmatched Quality

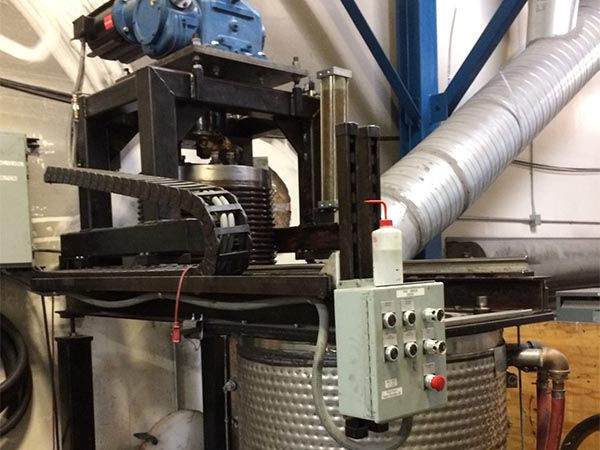

IPS is staffed by experts engaged from start to finish with precision machinery. Hot isostatic pressing, or HIPing, is a time-sensitive process that combines high temperature and pressure to improve the material properties of products used throughout the aerospace, biomedical, industrial, automotive, electronics, defense, and power generation industries.

HIP PROCESS

The hot isostatic pressing (HIP) process is a cost-effective method of fabrication that uses gas as the pressure-transmitting medium. This is one of the distinguishing factors of HIPing; the pressure is applied and forces the material to undergo equivalent, three-dimensional transformations. The heat and pressure make for a fully dense end product across simultaneous applications.

HIP MATERIALS

Our furnaces are contained within a vessel pressurized with an inert gas: argon, a noble gas, and one of the most abundant gases in the Earth’s atmosphere.

The uniform pressure and elevated temperature allow for densification, eliminating product defects while simultaneously improving the product’s mechanical properties.

Sister Companies

-

ITS in Olive Branch, Mississippi, provides quality toll services to the Southeastern United States as well as Mexico with a new NADCAP AC7102\6 certification.

ITS in Olive Branch, Mississippi, provides quality toll services to the Southeastern United States as well as Mexico with a new NADCAP AC7102\6 certification. -

AIP in Columbus, Ohio, has been in business since 1991. It supplies companies all over the world with both hot and cold isostatic presses.

AIP in Columbus, Ohio, has been in business since 1991. It supplies companies all over the world with both hot and cold isostatic presses. -

Isostatic Toll Services Bilbao SL is a brand new dedicated HIP facility located in Abanto Zierbena municipality in Biskaia.

Isostatic Toll Services Bilbao SL is a brand new dedicated HIP facility located in Abanto Zierbena municipality in Biskaia.

![]()

Isostatic Pressing

Industry Markets

Aerospace

-

Aircraft Engine Turbine Blades

-

Aircraft Components

-

Structural Aerospace Casting

View more information about our markets

Already Know What You Need?

Great! Send us the information about your parts and cycle parameters, and we will get back to you with the industry’s best price!

![]()

We’re happy to discuss your own hot isostatic pressing needs. Remember: With IPS, you’ll work from start to finish with friendly, experienced technicians who will assist you with optimizing your run parameters based on your specific product requirements.