Industries

Industry hums along worldwide, and Isostatic Pressing Services is there.

We’re there when high-performance engines are pushed to their limits and drivers are looking to squeeze every ounce of energy and efficiency from dynamic racing machines.

We’re there when jet engines pulse and fire as pilots fly higher and farther and faster with turbine blades rendered flawless by our HIPing processes.

And we’re there when an older runner returns to the hillside trails of his youth and conquers the terrain with the help of a newly implanted orthopedic knee component.

All these industries — along with a growing list of others — benefit from the experience and expertise of Isostatic Pressing Services’ highly responsive team of HIPing engineers.

We don’t construct the tibial implant; we make it stronger.

We don’t build the bulletproof vest; we make it lighter.

And we don’t engineer nuclear reactor cores; we push them forward into the far future.

IPS and its sister companies perform something akin to magic each and every time we partner with our industry mates.

We perfect and strengthen materials used across a wide range of specialties — from oil and gas extraction to biomedicine, aerospace, and more.

When these products exit our production line, they’re safer, more durable, and virtually indestructible.

It’s not magic; it’s science — and we wield it like pros.

IPS, LLC

Isostatic Pressing Services, LLC, is part of a family of companies. IPS is based in Oregon City, Oregon. Down in Mississippi, you’ll find Isostatic Toll Services, and in Ohio, it’s American Isostatic Presses.

Send us your parts; we’ll load up the vessels and send the finished products back to you — better and stronger than ever!

Industries seeking to work with IPS or one of its sister companies should find the following information relevant and helpful when deciding with whom to partner.

IPS in Oregon City, Oregon

Oregon is our newest facility. While we don’t manufacture equipment here as we do in Ohio, our focus remains steadfast on providing superior service and extraordinary responsiveness. The bulk of our Oregon City operations is geared toward medical implants, but we’re viable across a wide range of industries and HIPing processes and necessities.

ITS in Olive Branch, Mississippi

In Mississippi, Isostatic Toll Services (or ITS) is NADCAP-certified. The HIPing processes at this facility are calibrated for all manner of hot isostatic pressing, and their HIPing process is especially fine-tuned to work with the aerospace industry.

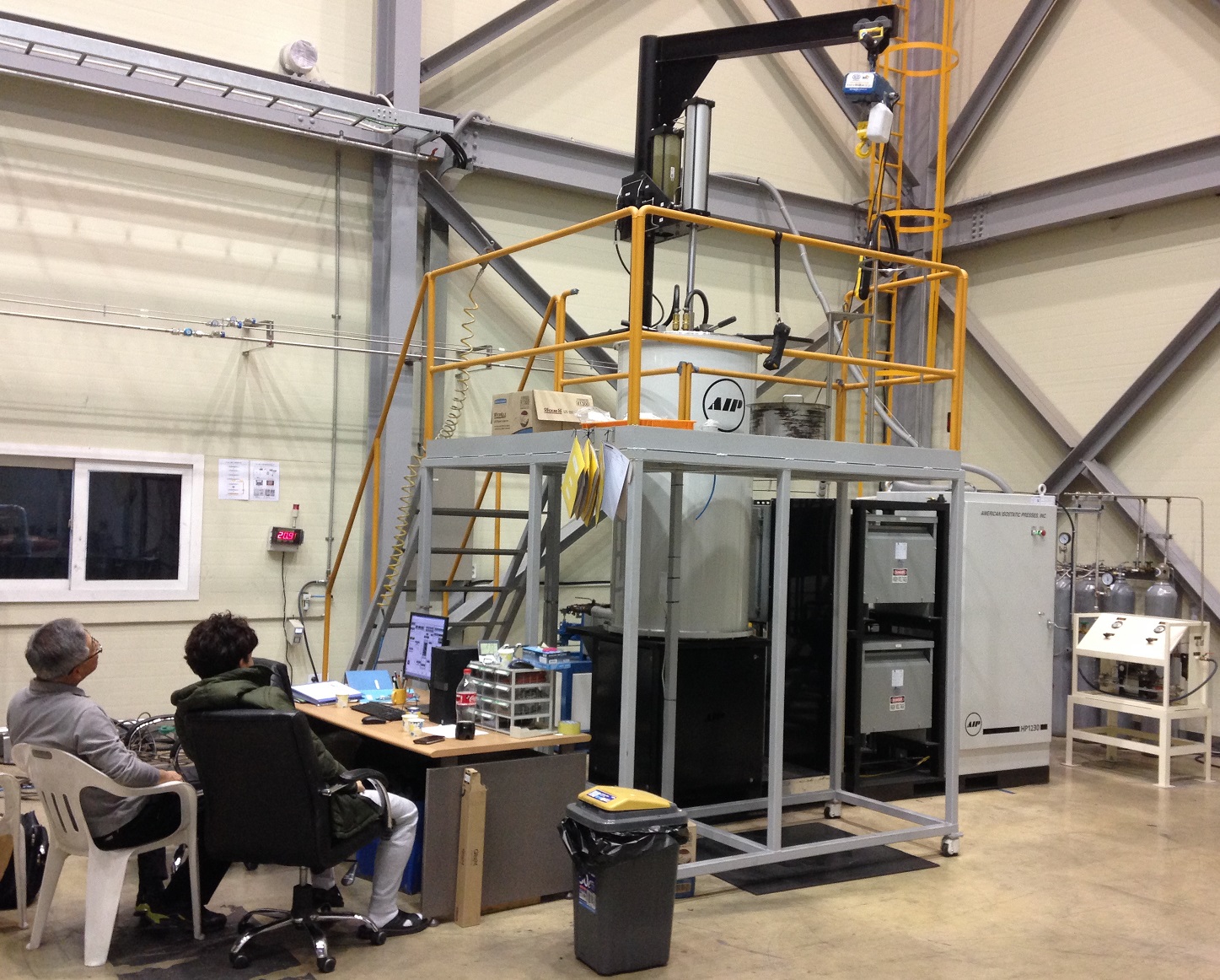

AIP in Columbus, Ohio

Finally, our sister company in Columbus, Ohio, American Isostatic Presses (or AIP) provides the same quality HIPing services and fast turnarounds as its counterparts down south and in the Pacific Northwest. But AIP also manufactures equipment, so our Midwest engineers focus their efforts on developing new technology.

Our companies rely on AIP for maintenance and new tech, including new materials and necessary and ongoing research and development. Our systems and our vessels are manufactured in Ohio, and we sell them all over the world.

With the combined knowledge and expertise of our three family-run and operated companies, we are perfectly positioned to provide industries worldwide with the world’s best HIPing services along with manufactured compressors, power transformers, and more.

Click the individual INDUSTRY pages in the menu to learn more.

Already Know What You Need?

Great! Send us the information about your parts and cycle parameters, and we will get back to you with the industry’s best price!

![]()

We’re happy to discuss your own hot isostatic pressing needs. Remember: With IPS, you’ll work from start to finish with friendly, experienced technicians who will assist you with optimizing your run parameters based on your specific product requirements.