Aerospace Technology fuels the aerospace industry. As it continues its upward trajectory, Isostatic Pressing Services is there, helping push the limits of what’s possible.

Browse All industries

When Isostatic Pressing Services partners with our colleagues in the aerospace industry, we do so knowing what’s in store: That we will become a crucial part of our clients’ operations. And that there can be no compromise on quality or room for negligence or carelessness.

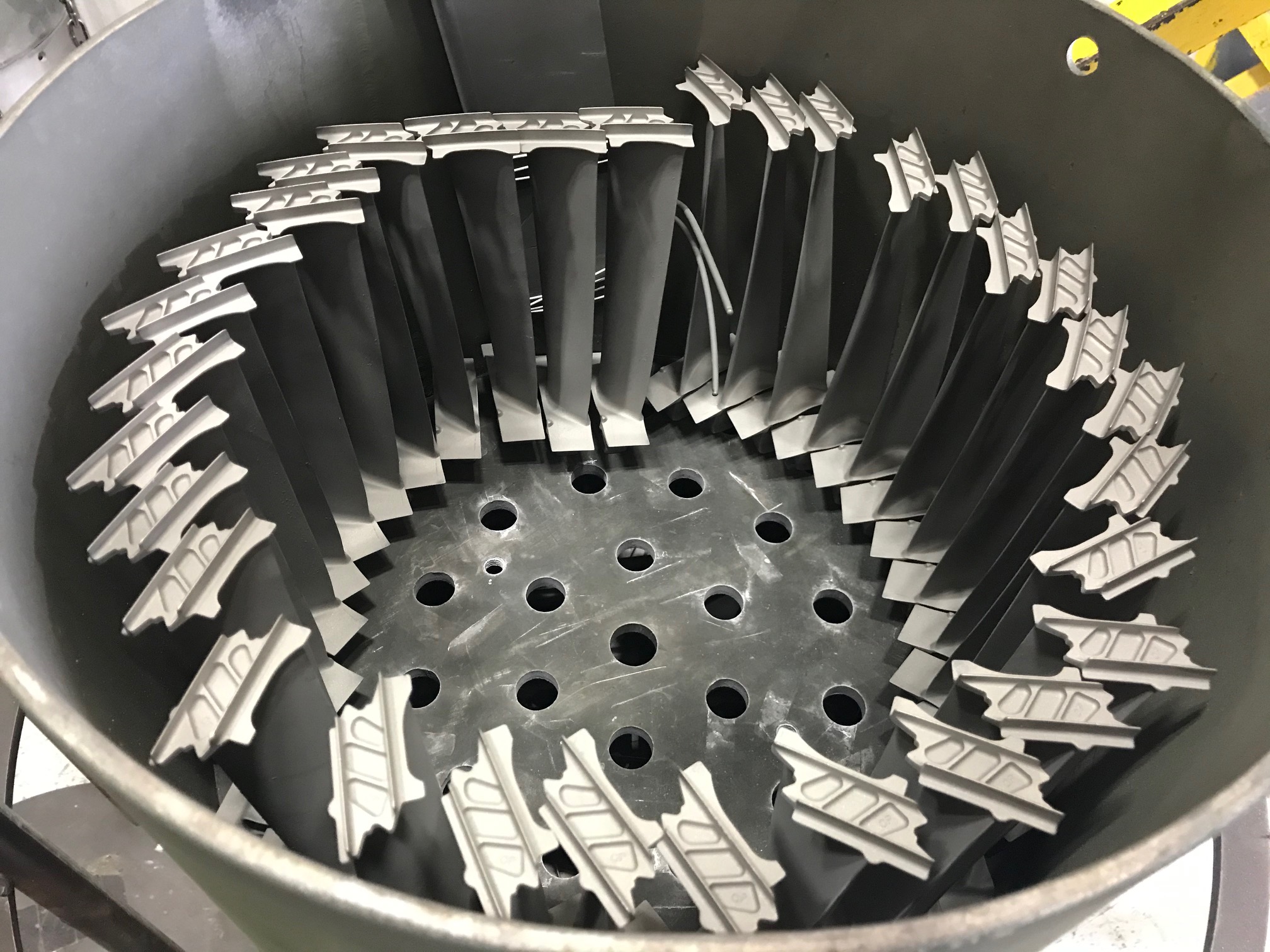

Our work in the aerospace industry deals primarily with jet aircraft engine components. This includes structural aerospace castings and turbine blades — processed at IPS in order to eliminate any potential defects that might compromise operational life and safety.

We take on these rigorous tasks wholeheartedly. Our commitment to precision means our HIPing systems adhere to the strictest fundamentals of the industry: no half-measures and nothing but the utmost attention to every detail.

It’s why so many of our clients return to us again and again to provide hot isostatic pressing services for their component parts. One of our chief advantages: We have access to our own manufactured machinery and vessels, which we obtain from our sister company in Ohio.

The IPS Advantage

Isostatic Pressing Services: Ready when you are!

- Fast turnaround

- Precise, computer-controlled with hard disk data logging

- Low cost

- Quality assurance

- Numerous shipping options

- Highly trained and experienced technicians and engineers

- System capabilities:

- 1260 degrees Celsius in argon

- 30,000 psi

- Molybdenum furnace capable of 1260 degrees Celsius in argon

- 10 degrees Celsius per minute heat ramp

- Temperature gradient: +/- 10 degrees Celsius

- Pressure control: +/- 250 psi

- Stainless steel load shelves

- Alumina plates (to prevent sticking)

There’s no reason to delay. Contact us right now!

We’re ready and available to discuss your hot isostatic pressing needs. We promise that you’ll be guided by experienced and friendly professionals.

Our work is done only by experienced technicians. They can assist with optimizing your run parameters based on your specific product requirements.

Already Know What You Need?

Great! Send us the information about your parts and cycle parameters, and we will get back to you with the industry’s best price!

![]()

We’re happy to discuss your own hot isostatic pressing needs. Remember: With IPS, you’ll work from start to finish with friendly, experienced technicians who will assist you with optimizing your run parameters based on your specific product requirements.